The Wright Brothers did not invent the wind tunnel but they were the first to use one for aircraft design.

The original Wright wind tunnel was of the ‘Open Circuit’ type.

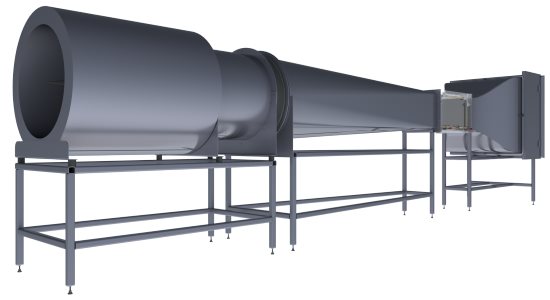

Open circuit wind tunnels, as the name implies, are a length of duct – the ends do not meet. Air is drawn into one end and exhausted out the other.

Much has been learned about aerodynamics and wind tunnels since 1871 when Frank H. Wenham invented the first wind tunnel. To efficiently produce a very smooth and stable flow, contemporary open circuit wind tunnels look different than those used by Wenham or the Wrights.

Open circuit wind tunnels can take many forms within two basic configurations; suction and blow-down. A fan (or series of fans) drives the airflow for both configurations. The difference between the two configurations is in the location of the fan. Fans are located near the exhaust end of a suction open circuit wind tunnel. In contrast, fans are located near the intake of a blow-down open circuit wind tunnel.

Both types have advantages and disadvantages. Contact The Wind Tunnel Company with your testing requirements and we will help you choose the best open circuit wind tunnel configuration and form for your needs.

Open Circuit Wind Tunnel Components:

Suction Tunnel Inlet: Open circuit wind tunnels consume laboratory air and the inlet is the entrance passage. The Wind Tunnel Company inlets have an elliptical shape to promote good downstream flow.

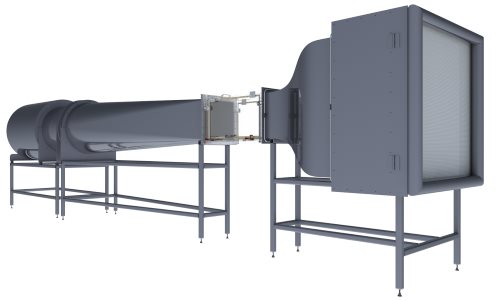

Flow Conditioning:

Incoming laboratory air is never perfectly smooth, straight or even. To correct this, a flow conditioning section is required.

To straighten the flow, a bank of parallel tubes is installed. Because these tubes are hexagonal in shape, this bank is referred to a ‘honeycomb’. The Wind Tunnel Company’s flow conditioning sections are fitted with removable honeycomb made of extruded aluminum.

To smooth the flow, a series of window-type screens (typically 2 or more) traverse the flow pathway. These screens act as a sieve and break apart eddies in the flow. They also serve to even the flow – faster moving areas of flow are slowed more through friction. These screens are referred to as ‘turbulence reducing screens’ or, more simply, as ‘turbulence screens’. The Wind Tunnel Company provides 2 stainless steel turbulence reducing screens with every open circuit wind tunnel. Additionally, extra space is provided in the flow conditioning section for another 2 optional screens if ultra-smooth flow is required for sensitive experiments.

Contraction:

The highly-contoured duct immediately upstream of the test section is the contraction.

The contraction serves to:

• accelerate the airstream

• reduce turbulence

• smooth the velocity distribution

Test Section:

The test section is the focal point of any wind tunnel. It is the duct section wherein the test item is mounted and studied. Because The Wind Tunnel Company specializes in custom design, we can work with you to create a test section to meet your exact needs.